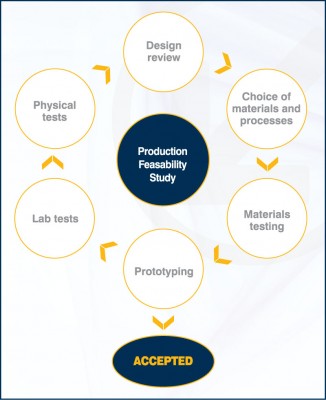

Development steps

Design review

In conjunction with the customer, review the product development or improvement designs (materials, shapes, processes).

Choice of materials and processes

Choice of materials and processes based on intended environment, required performance level, budgets, and any other elements identified during the design review.

Materials testing

Validation of material specifications for the required use and performance.

Prototyping (Levels 1, 2, 3)

Manufacture of Level 1 prototype, preliminary function test (shape, adhesion, etc.).

Manufacture of Level 2 prototype, prototype mould, or by hand using different materials, physical tests (in actual use conditions).

Manufacture of Level 3 prototype, mould production, final material selected, production assembly testing.

Lab tests

Lab tests performed in-house and/or by approved external laboratories, according to customer specifications.

Physical tests

Physical tests in actual use conditions by the customer.